|

|

MetalWorks Inc.(https://www.metalworksinc.net/) has built a strong reputation as a trusted contract manufacturer of high-quality metal components and assemblies for a wide range of industries. Combining precision craftsmanship with advanced manufacturing and inspection processes, every part the company produces is of exceptional quality.

Since its founding in 1997 in a modest Nebraska warehouse, MetalWorks has expanded to six manufacturing sites and built a reputation as a go-to partner for OEMs that require precision metal parts manufactured to spec and delivered on time.

MetalWorks’ growth trajectory is a result of its commitment to leveraging the latest design and manufacturing technologies to successfully compete and grow in the contract manufacturing market. That’s why the company implemented Dassault Systèmes SOLIDWORKS® design and machining solutions in 2019, according to Quick Response Manufacturing Designer Todd Blacksher. “We realized productivity gains when we started using SOLIDWORKS CAM for 2½-axis machining, which makes up most of our work,” Blacksher recounts.

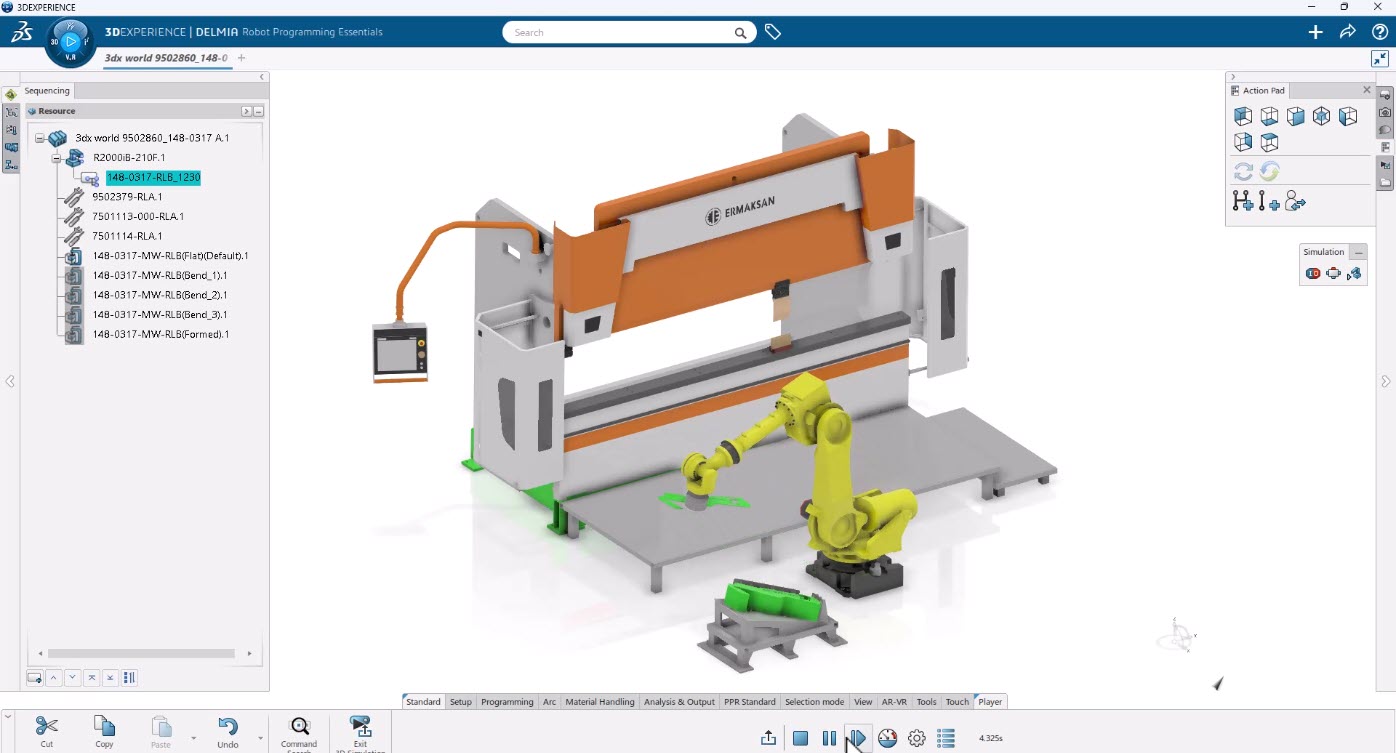

MetalWorks’ increased use of robotic technology for production—currently 27 robots at six different locations—required a solution for remote programming of robotic cells to increase efficiencies and robot uptime. Before 2025, programming MetalWorks robots meant physically walking up to it, pendant in hand, and taking it offline to load or modify code. That slow and inefficient process created unacceptable production delays.

“We saw a demo for Robot Programmer from our SOLIDWORKS reseller GoEngineer, and chose to add those solutions to leverage the cloud-based 3DEXPERIENCE® platform for offline programming of manufacturing robots,” notes Blacksher.

The shift toward offline robot programming—creating and testing robot instructions on a computer while the robot continues to run—has helped MetalWorks dramatically reduce downtime, increase throughput, and better allocate both human and machine resources. “We’re getting close to 30 robots right now,” says Blackshear. “I can program any of them from my desk.”

Instead of traveling to a facility or halting a robot mid-shift, now Blacksher can create and virtually simulate programs remotely while the robot keeps working. “I do all the work while it’s doing production, so I don’t affect the robot in any way,” he says.

That means the setup for the next job can begin before the current one is finished.

Unlike manufacturers that keep the same robotic program running jobs for days or weeks, MetalWorks frequently switches jobs throughout each day. “Each robot might have 30 to 50 different programs that can be run at any time,” explains Blacksher.

Offline programming makes those transitions seamless. Programs can be fine-tuned in advance and uploaded quickly, without idle time. And, offline programming also strengthens the quoting process by reducing turnaround times. Programs can be prepared in advance based on a quote, so production can begin immediately once an order is confirmed.

In addition, with better planning and support from the SOLIDWORKS team, MetalWorks has created a repeatable, scalable process that streamlines it, maximizes human and machine resources, and increases revenue.

|

|

|小黑屋|手机版|Archiver|机械荟萃山庄

( 辽ICP备16011317号-1 )

|小黑屋|手机版|Archiver|机械荟萃山庄

( 辽ICP备16011317号-1 )